Biscuit Plate Joiner Makita PJ7000

General application of biscuit joins

Biscuit joinery has a wide huge variety of applications. Initially the main purpose for a biscuit plate joiner might be building tables out of several boards and carcass making.

The big advantages are quick, perfectly aligned results and they are adequate strong for most applications.

It also can even be used to just get two pieces perfectly aligned to each other for later applying a stronger type of joint.

The application is pretty easy:

Just align the two joining pieces to their later end position and mark them both at the same position. The rest is history :) You take each piece and align it to the biscuit joiner fence with your mark aligned to the mark on the fence. Then just mill the slots on each piece put some glue in 'em, put it together and clamp it. That’s it.

My experiences with the Makita PJ7000

When I started woodworking I quickly realized that a biscuit joiner makes a woodworker’s life so much easier.

I am (yet ? :) ) not a big fan of pocket holes (even if this technique also does a good job on some applications) since I try to avoid using screws when building my own furniture.

I think the most reliable, durable, long lasting and best looking (or lets say ‚invisible‘) joints are made out of wood and glue. But that’s just my opinion, there are applications where you don’t may have the time to wait until the glue has dried.

The PJ7000 is so convenient to use that I use and have used it in almost all my woodworking projects. Just have a look at my project videos like my build of the 'Monitor stand and desk organizer‘, my build of a 'drawer cabinet‘ or the build of my 'glowing pallet coffee table‘.

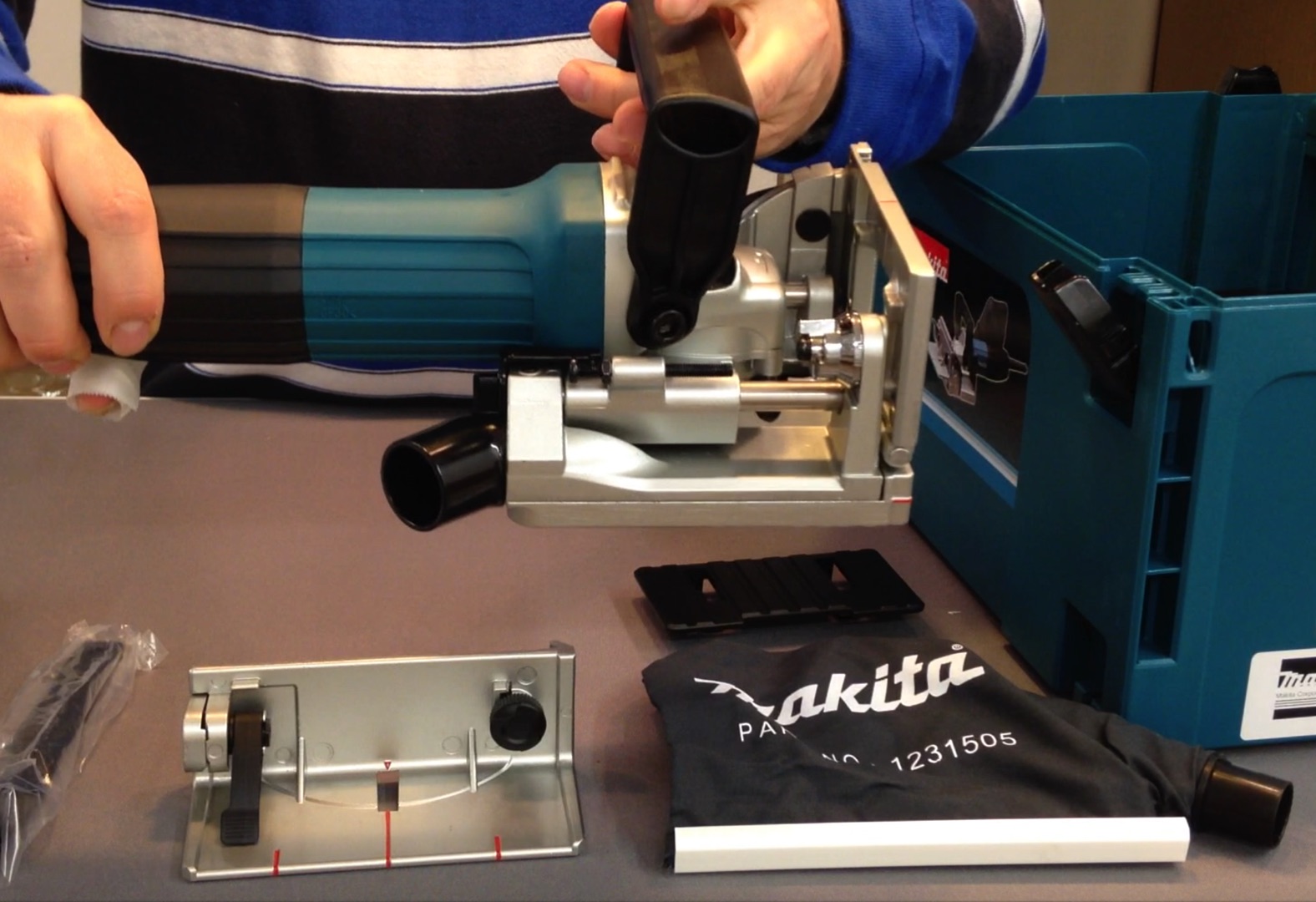

The PJ7000 comes in a box:

• 1 x Makita PJ7000

• 1 x Cutter blade 100-4

• 1 x Angle guide

• 1 x Lock nut wrench

• 1 x Set plate

• 1 x Dust bag

• 1 x Carry case

Capacity:

• Blade diameter 100mm

• Blade thickness 4mm

• Hole diameter 22mm

Powered by a 700 watt motor to deliver up to 11,000 rpm, for precise cutting into wood.

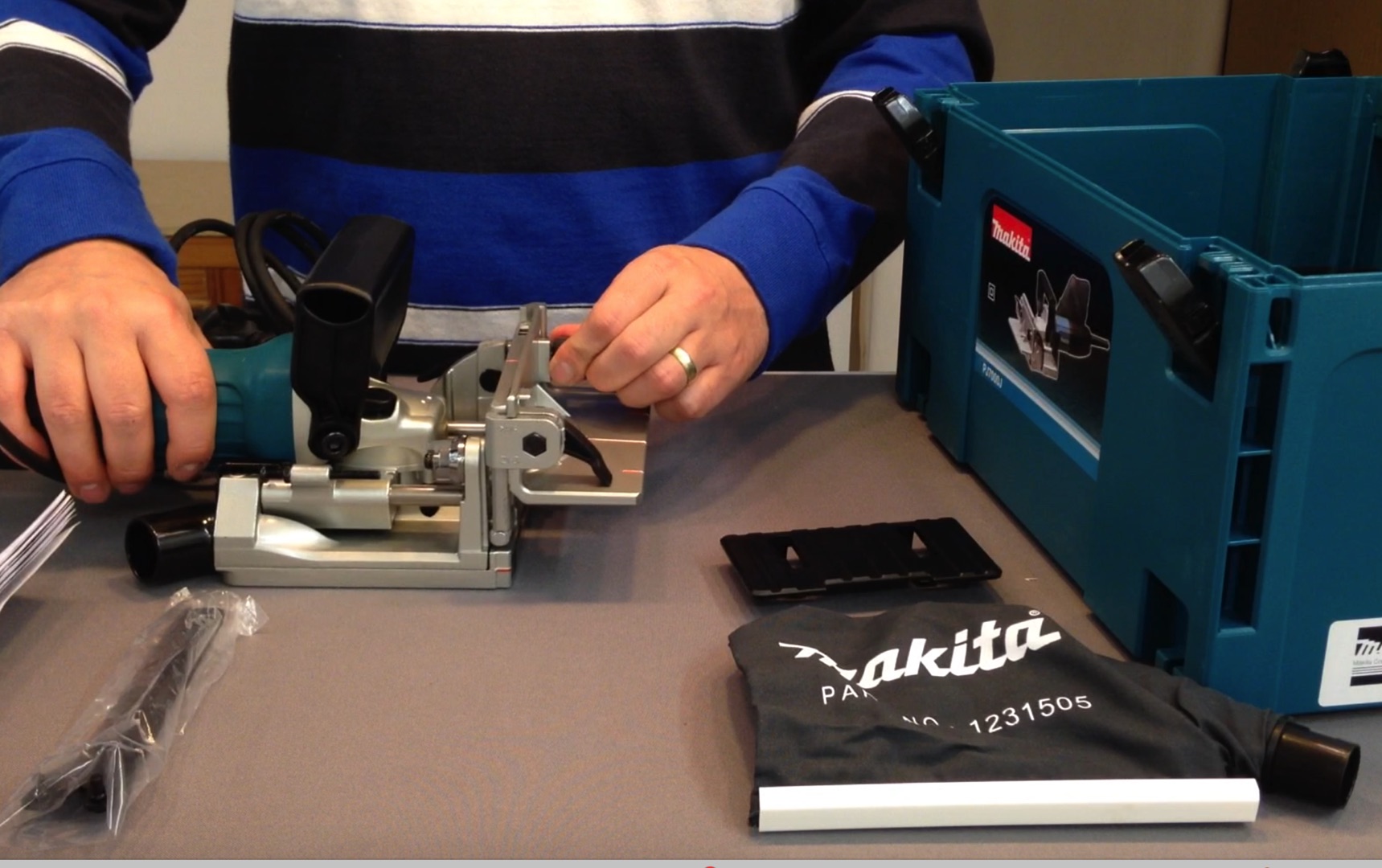

The Biscuit Jointer features six pre-set cutting depth settings, with one touch stops for 0, 10 and 20 for the most common biscuit sizes. The blade cover can be opened with clamp screws for easy blade change and the shaft locks for quick and easy blade changes.

Large and easy to operate cam locks for the fence adjustments, angle adjustable with positive stops at 0, 45 and 90 degrees. Rack and pinion vertical fence system for accurate fence adjustments.

It also provides a dust nozzle for connection to a dust extraction but in most cases I use the enclosed dust bag hence to better maneuverability.

The Makita PJ7000 does a great job on all applications of biscuit joints. It is very handy and provides an awesome quality and produces great result.

Even this tool might not be the cheapest, it will enhance your working process ultimately.

If you consider buying one at amazon, I really would be stoned if you would use one of my links below for a little support :-)

Watch the Unboxing Video on my channel

Hope to have one soon

Write a comment